How Cold-Chain Solutions Keep Food Fresh and Farmers Profitable in a Warming World

As the Festival of Cooling, the world’s first global event dedicated to sustainable cooling and cold-chain innovation, takes place in Kigali from October 6 to 10, 2025, the conversation about how to keep food fresh and farmers profitable in a warming world is taking center stage.

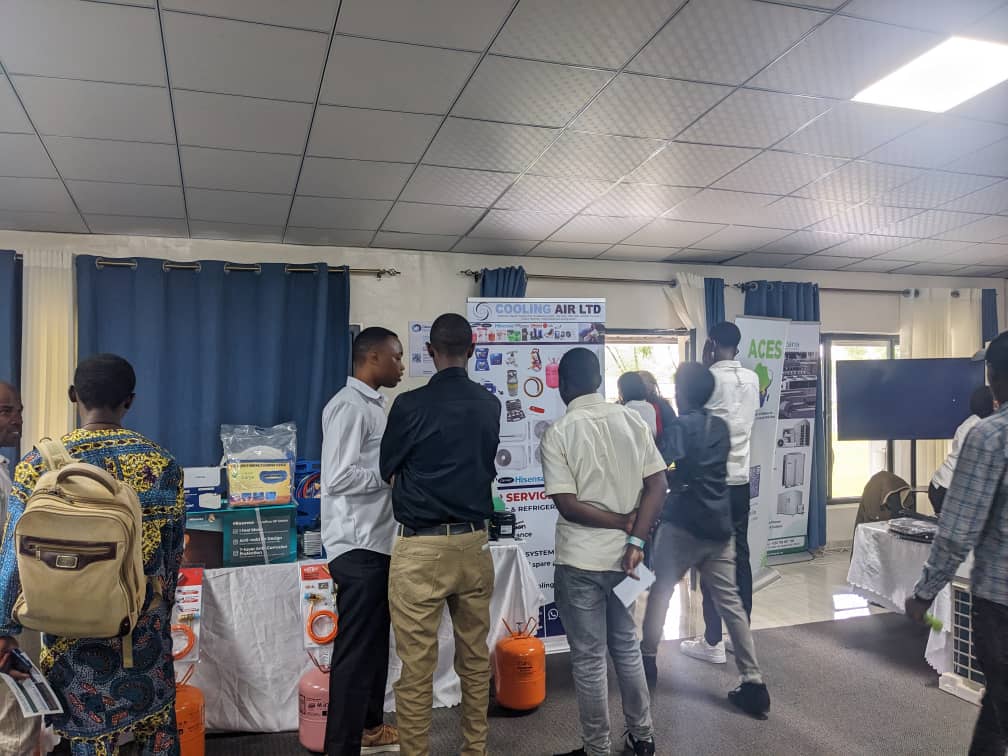

Hosted at the Africa Centre of Excellence for Sustainable Cooling and Cold-Chain (ACES) on the University of Rwanda’s Rubirizi Campus, the week-long event has brought together farmers, scientists, innovators, and policymakers from across the globe to showcase climate-smart cooling technologies designed to keep food fresh, vaccines potent, and communities resilient.

ALSO READ: Rwanda’s Festival of Cooling: The Hidden Backbone of Food and Health Security

For many African farmers, especially smallholders, the journey from farm to market is fraught with losses. Without cold storage or refrigerated transport, much of their hard work perishes before ever reaching consumers. But as the world warms, sustainable cold-chain systems, technologies that keep produce at optimal temperatures from harvest to consumption, are offering new hope.

Cutting Losses, Increasing Value

Among the exhibitors at this Festival of Cooling is Zachary Kibiri, a member of the Lari Horticulture Cooperative Society from Kenya. His cooperative is already reaping the benefits of using cold-chain technologies to reduce food waste and boost farmers’ incomes.

“Without a cold-chain, farmers experience as high as 50% of their produce going to waste,” Kibiri said. “Now, since we started using cold rooms, we’ve reduced post-harvest losses to about 10%, and even that remaining 10% is only because some small sizes don’t meet market grades.”

The transformation is striking. Before adopting cooling technologies, Kibiri and fellow farmers sold cabbages for about 15 to 20 Kenyan shillings. “Today, we sell the same cabbage for 55 to 60 shillings,” he added proudly. “That’s almost three times more, and we can now deliver to distant markets because our produce stays fresh.”

Beyond reducing waste, cold-chain systems have unlocked new opportunities for value addition, processing and packaging that turn raw produce into market-ready goods. “When we start doing value addition, even the 10% that doesn’t make it to the cold room can be utilized,” Kibiri explained. “We can sell up to 97% of our produce, and that means higher profits for farmers.”

Keeping Freshness from Field to Fork

The cold-chain operates on a simple principle: control temperature at every step. From pre-cooling at the farm to cold storage and refrigerated transport, each phase helps preserve the quality of perishable produce.

“All crops cannot be kept at the same temperature,” Kibiri noted. “Bananas, carrots, and spinach each require different storage conditions. If you put them at the same temperature, some will spoil. But when you keep them under the right conditions, they can last up to seven or even eight days, still fresh and market-ready.”

The result is not just better income, but higher consumer satisfaction. “Without cooling, consumers get substandard products,” he said. “With cold-chain, the freshness is maintained from harvest to the table.”

Cooling as Critical Infrastructure

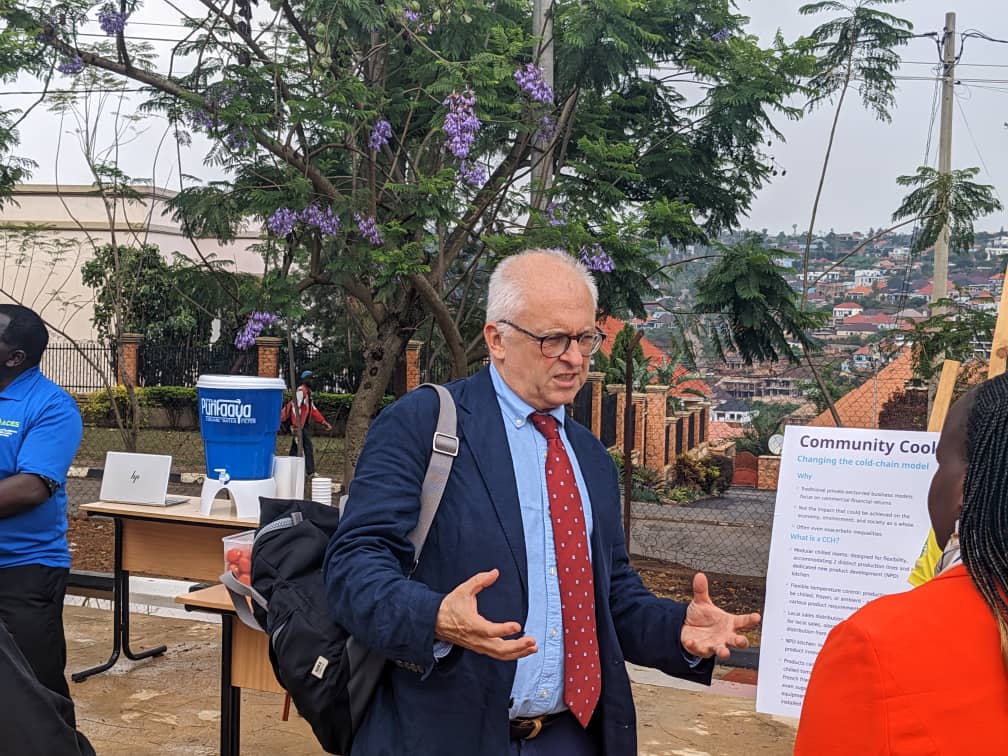

For Prof. Toby Peters, Founding Director of ACES, the cold-chain is not merely a technology, it is critical infrastructure. “The cold chain is as important as a water pipe or electricity cable,” he said. “It moves essential products, food and health items, from farm to market or from manufacturer to consumer.”

He pointed to staggering statistics: Sub-Saharan Africa loses more than 37% of its food production between harvest and market, equivalent to 120 to 170 kilograms per person each year. “This unnecessary loss not only deprives people of healthy nutrition but also devastates farmers’ incomes and holds back rural economies,” he said.

By integrating pre-cooling, cold storage, and refrigerated transport, Peters believes farmers can extend shelf life, connect to wider markets, and facilitate exports. “Imagine the transformation in financial well-being if farmers in Rwanda’s Ngoma, Huye, Musanze, Rubavu, Rusizi, or Nyagatare districts could store their produce longer, reduce losses, and sell later at better prices,” he said.

Turning Farmers into Price-Makers

Globally, farmers capture only about 25% of food value chains, but cooling could change that. In Africa, limited food processing means only $40 of value is added per tonne of produce, five times less than in high-income countries.

“Cooling enables local storage, improved quality, and processing,” Peters explained. “Farmers and cooperatives can create branded products, from juices to dried fruits, so they can move from being price-takers to price-makers. That’s how we build competitive agro-industries that earn foreign exchange and strengthen resilience.”

A National Priority for Rwanda

For Rwanda, reducing post-harvest losses is a key priority under the National Strategy for Transformation (NST2) and the Strategic Plan for Agriculture Transformation (PSTA 5), which aim to cut losses in staple crops from 13.8% in 2023 to 8% by 2029.

“We’re not going to deliver the aspirations of Rwanda Vision 2050 without a robust cold-chain,” Peters said. “This event, the Festival of Cooling, is about making cooling visible, accessible, and fun, but also inclusive and affordable.”

ACES is working to train refrigeration engineers, help farmers choose the right technologies, and develop cooperative business models. “Cooling cannot be exclusive,” Peters emphasized. “It has to be inclusive and affordable. That’s what we’re building here in Kigali.”

SUBSCRIBE TO OUR NEWSLETTER